There are some parts of rod building that are considered boring and tedious. One of them is grinding guide feet. Yawn…

But, if you are spending a lot of time and money to make your custom build ‘One-Of-A-Kind’ then you need to pay attention to all the details. One of those details is guide feet.

This rod building tip applies to all types of guides for fly rods, spinning rods, boat rods, it doesn’t matter what kind of rod.

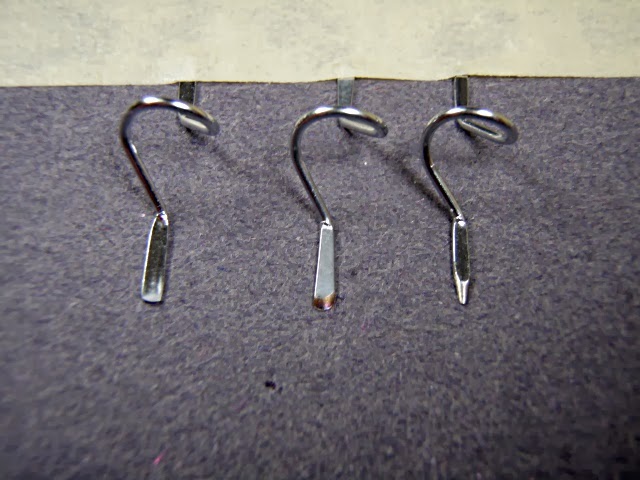

First, the purpose of grinding guides is to make wrapping your thread up over the guide foot smooth and easy. If not properly ground, you may get gaps and struggle a bit to get the thread up over the edge of the guide. The image below show the difference between ‘unground’ and ‘ground’ guides. Most rod guides come pre-ground from the manufacturer but I don’t consider them finished to the point that I prefer. I still take the time to ‘finish’ grinding before wrapping. I use a grinding wheel but you can use a file or sandpaper, it will just take a bit longer doing it by hand.

|

| Unground, factory ground & how we do it! |

Not only do I grind the front of the foot but also the sides to reduce the width of the guides. I do this only when I think the guide foot is too wide for the blank I’m wrapping. I also take a moment and run the bottom of the foot across 220 grit sandpaper just to remove any side or bottom burrs. If you run your guide across your finger and it feels like there’s a edge, your nylon or silk thread will certainly find the burr. Also with a smooth foot, the guide is less likely to dig into the blank and scratch the rod finish.

It only takes a few minutes to really dress the guide feet especially if you are using a transparent thread wrap the guide feet will look finished and even.